Short Lead Time for Food Machinery Casting Foundry - Pump Valve – Yungong

Short Lead Time for Food Machinery Casting Foundry - Pump Valve – Yungong Detail:

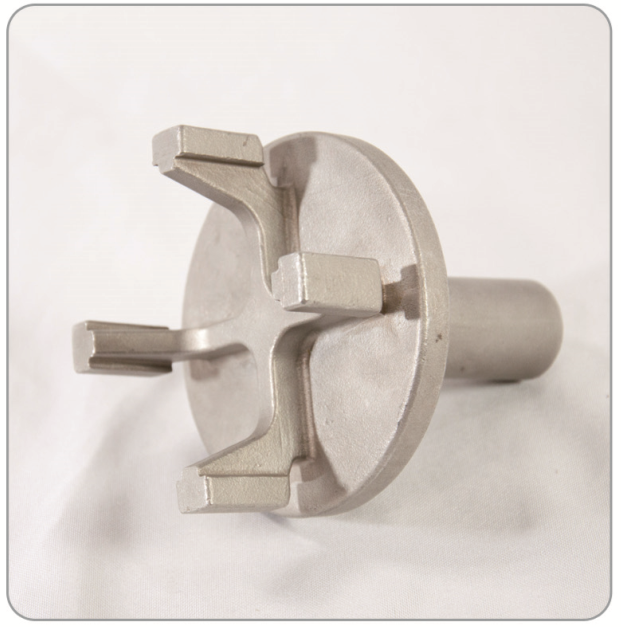

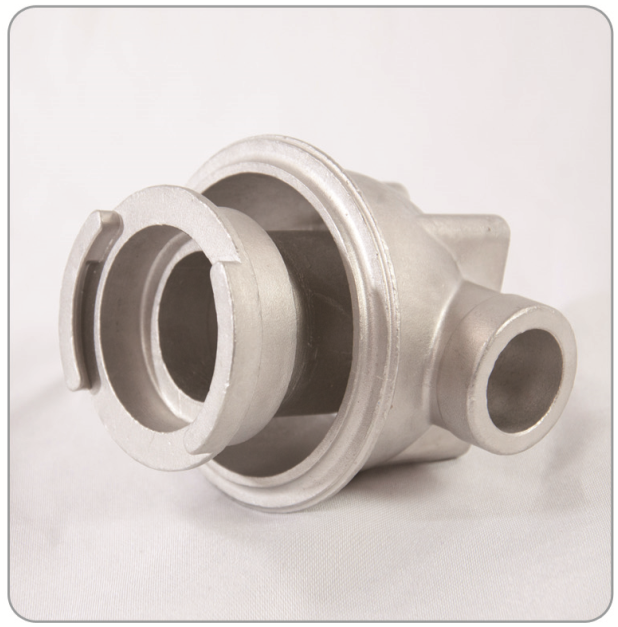

Pump & Valve Component Castings:

The investment casting process provides tremendous design freedom and allows us to create a wide range of parts, Gate valves, Plug valves, Rotary control valves.

We cast various parts for hydraulic and pneumatic equipment including:

Yungong Technology do OEMlost was investment casting as per your drawing or samples or your requirement.

Serving customers with a package solution in terms of optimizing design of parts, casting, machining, heat-treatment and finish so that our customers can cut down costs in their products and obtain value-added parts.

Casting uses the liquid form of metal to create valves.

These metals are melted into a molten liquid and poured into various molds.

One of the biggest benefits of casting is that it can create valves with complex shapes, patterns, and sizes.

Home-stainless steel precision castings, The material has AISI 304,AISI 316,CF8,CF8M,CF3M,Carbon Steel and Alloy Steel.

A wide range of carbon steel, low alloy steel and Stainless Steel are available on customer’s specifications.

Products cover wide application: auto parts, machining parts, chemical industry, mining industry, engineering machineries, marine parts, automobile casting parts, and general casting parts, construction machinery industry, blades and vanes for turbines, medical parts, machining mechanical parts.

Product detail pictures:

Related Product Guide:

How is the strength of the silica sol shell made?

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Short Lead Time for Food Machinery Casting Foundry - Pump Valve – Yungong , The product will supply to all over the world, such as: Israel, Colombia, Belgium, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

Products description

precision casting stainless steel parts have a wide range of applications. The precision casting are widely used in aviation, navigation, medical, mining, automotive, decoration, food machinery and other industries .

our casting including pump valve , Pipe fittings, impeller, nozzle, Marine accessories, energy and mineral accessories. Auto parts, Food machinery accessories, Fire escape fittings, medical device accessories, decoration parts

our factory

Shijiazhuang Yungong technology company Located in Xing tang County Economic and Technological Development Zone, Shijiazhuang City, He bei Province,The company covers an area of twenty thousand square meters .It is a large investment casting production base with more than 300 employees,

we have research and development, design. Manufacture. Sale and after service departments.

The company is mainly engaged in precision casting .Our precision casting uses medium temperature wax. Silica sol shell making process

Products picture

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,