Short Lead Time for Foundry Mould - Hardware casting – stainless steel casting – Yungong

Short Lead Time for Foundry Mould - Hardware casting – stainless steel casting – Yungong Detail:

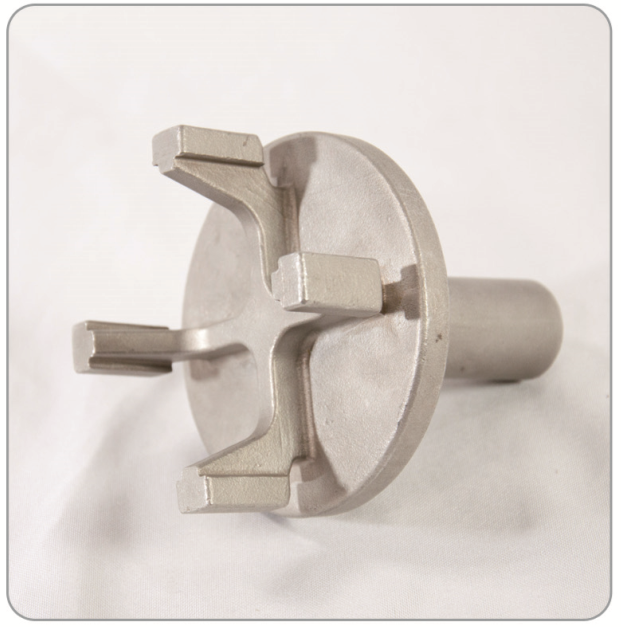

Metal decoration

Material: Carbon Steel, Alloy Steel, Stainless Steel

Items: FOB Xingtang, CIF XXX, Transportation by Sea

Lead time: 30~40 days

Place of origin: China

Software for specification drawings: PDF, Auto CAD, Solid work, JPG, ProE

Surface treatment: Mirror polishing

We manufacture precision cast metal parts that consistently meet or exceed customer expectations.

Lost wax investment casting allows us to produce metal parts in different weight, in a wide range of material choices.

The lost wax casting process produces near-net-shape precision metal parts that often require little to no additional machining.

The resulting finish is also much better than what is achievable through most other processes.

And, the strength and durability of cast metal parts makes them ideal for high wear applications requiring millions of cycles.

A wide range of applying areas:

Valve castings

Manifolds

Castings for pump parts & housings

Hardware, lock & hinge metal castings

Precision medical castings

Dental parts castings

Castings for military & firearm parts

Hand tool parts castings

Aerospace and aviation parts

And more

The investment casting process offers numerous benefits:

Allows many intricate and complex forms to be cast

The resulting parts have smooth surfaces with no parting lines.

A vast array of alloys can be used, ferrous or non-ferrous, including alloys of aluminium, bronze or magnesium, cast iron, carbon steel and stainless steel (as well as materials that can be difficult to machine).

Parts have good dimensional accuracy.

Allows for both low and high-volume manufacturing.

Cost of production is reduced, since waste is minimal and it doesn’t require too much assembly.

It’s also possible to add names, logos or numbers to the parts.

This type of casting also allows the production of small parts with a high level of accuracy, repeatability and integrity. A ceramic mould is used to create an exact duplicate of the component, and the need for secondary machining can be reduced, since the investment castings are created to shape.

Product detail pictures:

Related Product Guide:

How is the strength of the silica sol shell made?

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Short Lead Time for Foundry Mould - Hardware casting – stainless steel casting – Yungong , The product will supply to all over the world, such as: Adelaide, Switzerland, Croatia, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Products description

precision casting stainless steel parts have a wide range of applications. The precision casting are widely used in aviation, navigation, medical, mining, automotive, decoration, food machinery and other industries .

our casting including pump valve , Pipe fittings, impeller, nozzle, Marine accessories, energy and mineral accessories. Auto parts, Food machinery accessories, Fire escape fittings, medical device accessories, decoration parts

our factory

Shijiazhuang Yungong technology company Located in Xing tang County Economic and Technological Development Zone, Shijiazhuang City, He bei Province,The company covers an area of twenty thousand square meters .It is a large investment casting production base with more than 300 employees,

we have research and development, design. Manufacture. Sale and after service departments.

The company is mainly engaged in precision casting .Our precision casting uses medium temperature wax. Silica sol shell making process

Products picture

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.