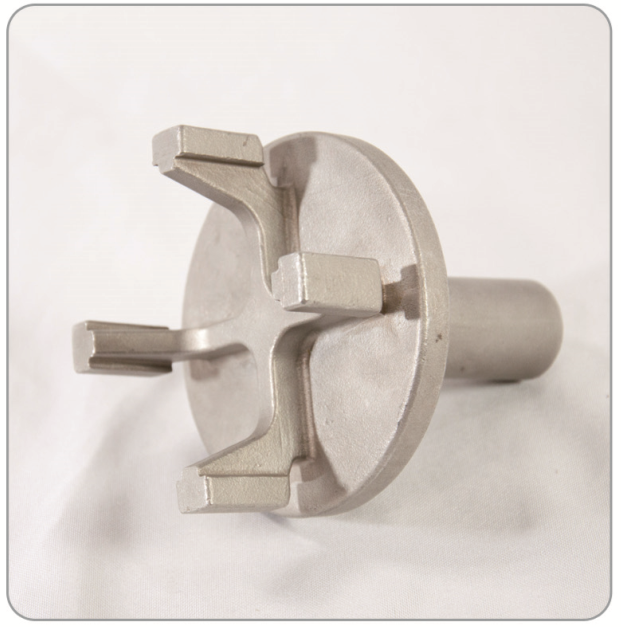

Well-designed Investment Casting Suppliers - Pump Fittings Casting, Steel Casting Impeller, Pump Casting Vane Wheel, Stainless Steel Casting Pump Runner, Pump Impeller Casting, Pump Parts – Yungong

Well-designed Investment Casting Suppliers - Pump Fittings Casting, Steel Casting Impeller, Pump Casting Vane Wheel, Stainless Steel Casting Pump Runner, Pump Impeller Casting, Pump Parts – Yungong Detail:

Application on:

An impeller is a rotor used to increase the pressure and flow of a fluid.

An impeller is a rotating component of a centrifugal pump, usually made of iron, steel, bronze, brass, aluminum or plastic, which transfers energy from the motor that drives the pump to the fluid being pumped by accelerating the fluid outwards from the center of rotation.

The velocity achieved by the impeller transfers into pressure when the outward movement of the fluid is confined by the pump casing. Impellers are usually short cylinders with an open inlet (called an eye) to accept incoming fluid, vanes to push the fluid radially, and a splined, keyed or threaded bore to accept a drive-shaft.

The impeller made out of cast material in many cases may be called rotor, also.

It is cheaper to cast the radial impeller right in the support it is fitted on, which is put in motion by the gearbox from an electric motor, combustion engine or by steam driven turbine.

The rotor usually names both the spindle and the impeller when they are mounted by bolts.

Material Grades:

Cast Steel, Carbon Steel, Alloy Steel, Mild Steel, Medium Carbon Steel, High Carbon Steel

How to control the quality ?

We have inspector to check the process step by step , so that can control the quality .

1. Confirm drawing and detail with customer , as well as manufacturer.

2. Make sample and offer first sample report according customer.

3. Start mass-production after sample released.

4. Raw material checked when come to factory.

5. Each process step checked by inspector.

6. QC report and samples send to customer after mass-production , or third party inspect.

Product detail pictures:

Related Product Guide:

How is the strength of the silica sol shell made?

To meet the customers' over-expected pleasure , now we have our potent staff to offer our great general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Well-designed Investment Casting Suppliers - Pump Fittings Casting, Steel Casting Impeller, Pump Casting Vane Wheel, Stainless Steel Casting Pump Runner, Pump Impeller Casting, Pump Parts – Yungong , The product will supply to all over the world, such as: Kyrgyzstan, Honduras, Ethiopia, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the high quality products with lower price. We've been looking forward to doing business with you!

Products description

precision casting stainless steel parts have a wide range of applications. The precision casting are widely used in aviation, navigation, medical, mining, automotive, decoration, food machinery and other industries .

our casting including pump valve , Pipe fittings, impeller, nozzle, Marine accessories, energy and mineral accessories. Auto parts, Food machinery accessories, Fire escape fittings, medical device accessories, decoration parts

our factory

Shijiazhuang Yungong technology company Located in Xing tang County Economic and Technological Development Zone, Shijiazhuang City, He bei Province,The company covers an area of twenty thousand square meters .It is a large investment casting production base with more than 300 employees,

we have research and development, design. Manufacture. Sale and after service departments.

The company is mainly engaged in precision casting .Our precision casting uses medium temperature wax. Silica sol shell making process

Products picture

A good manufacturers, we have cooperated twice, good quality and good service attitude.